Log In

Find similar

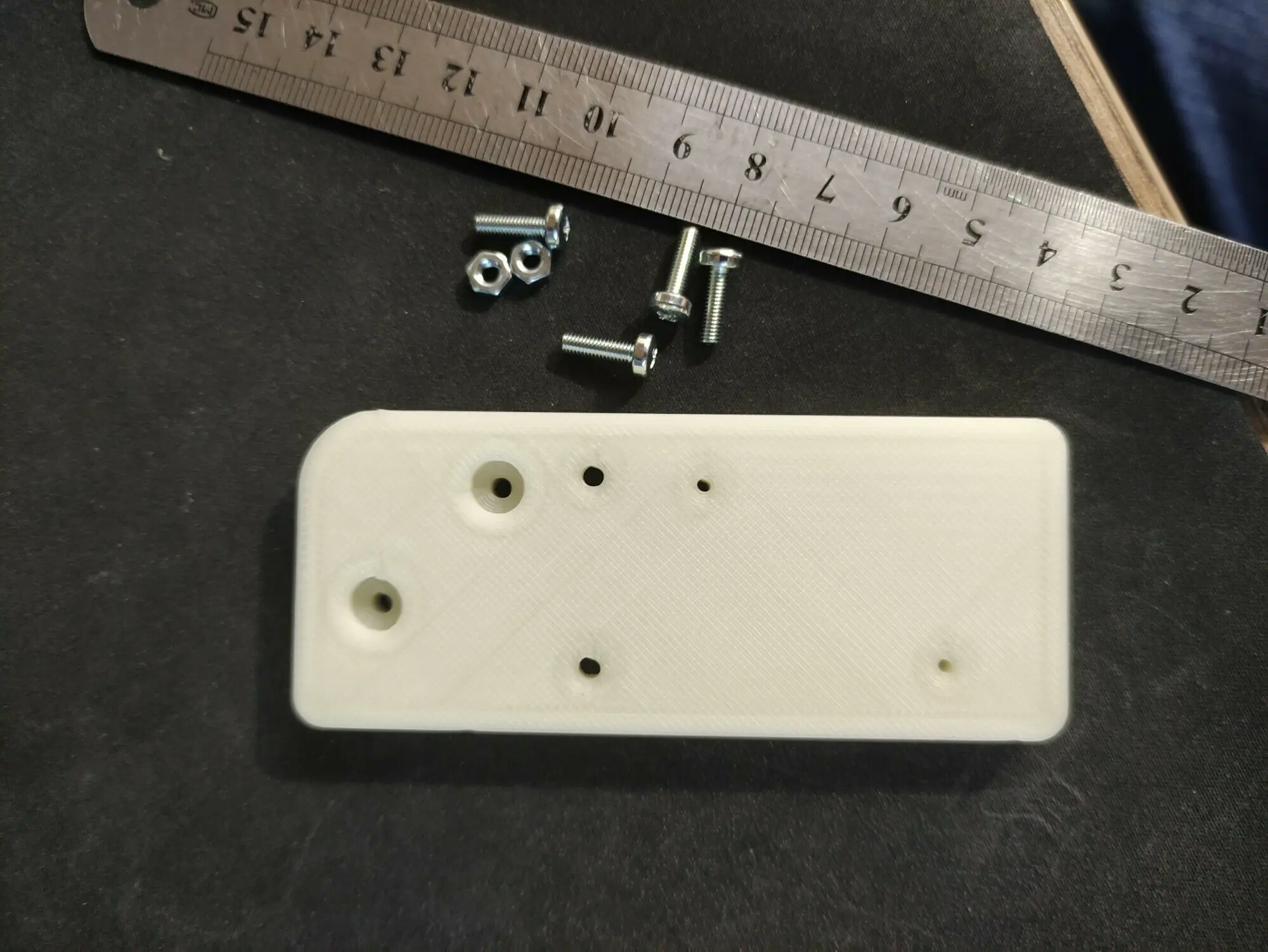

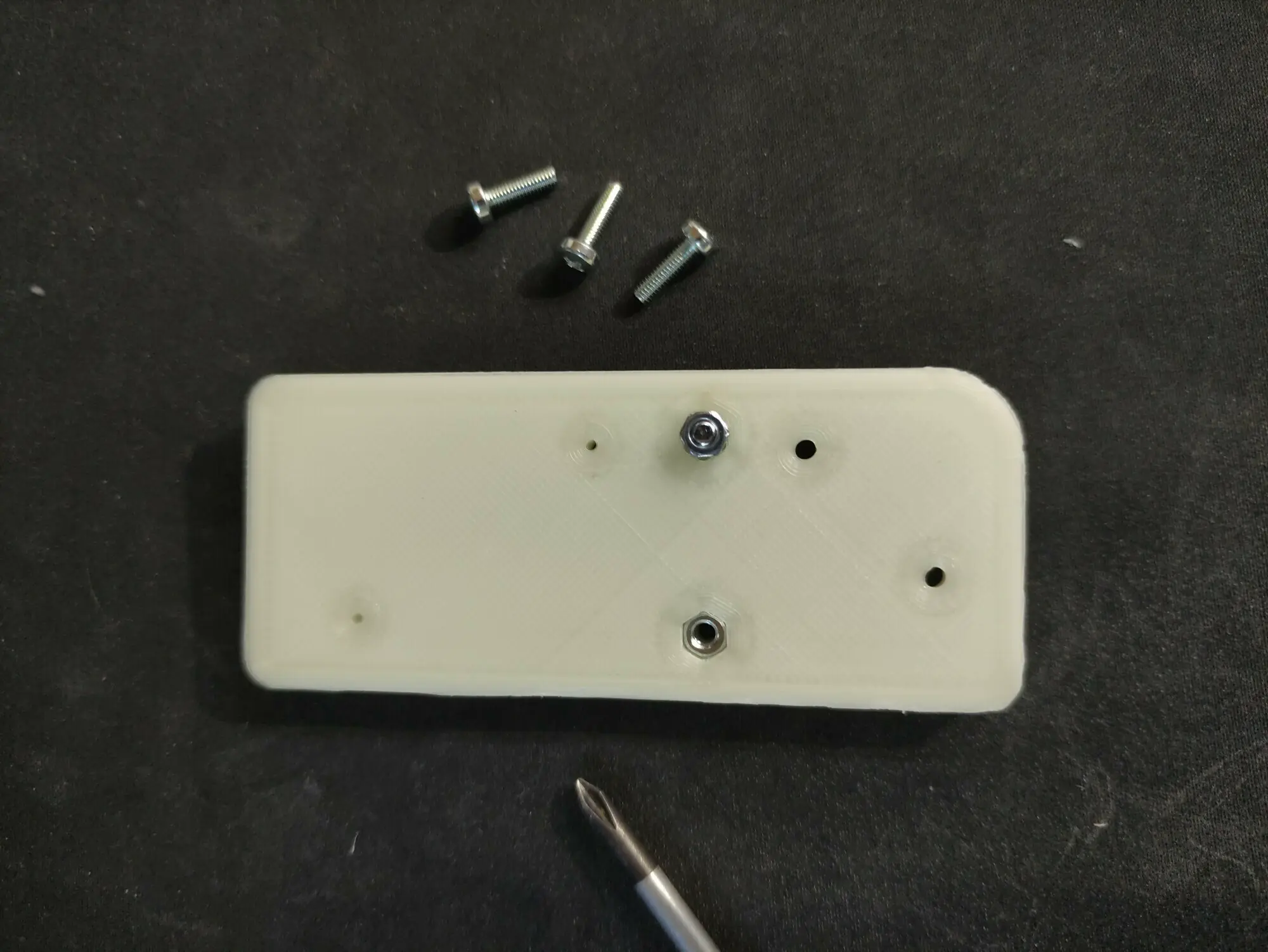

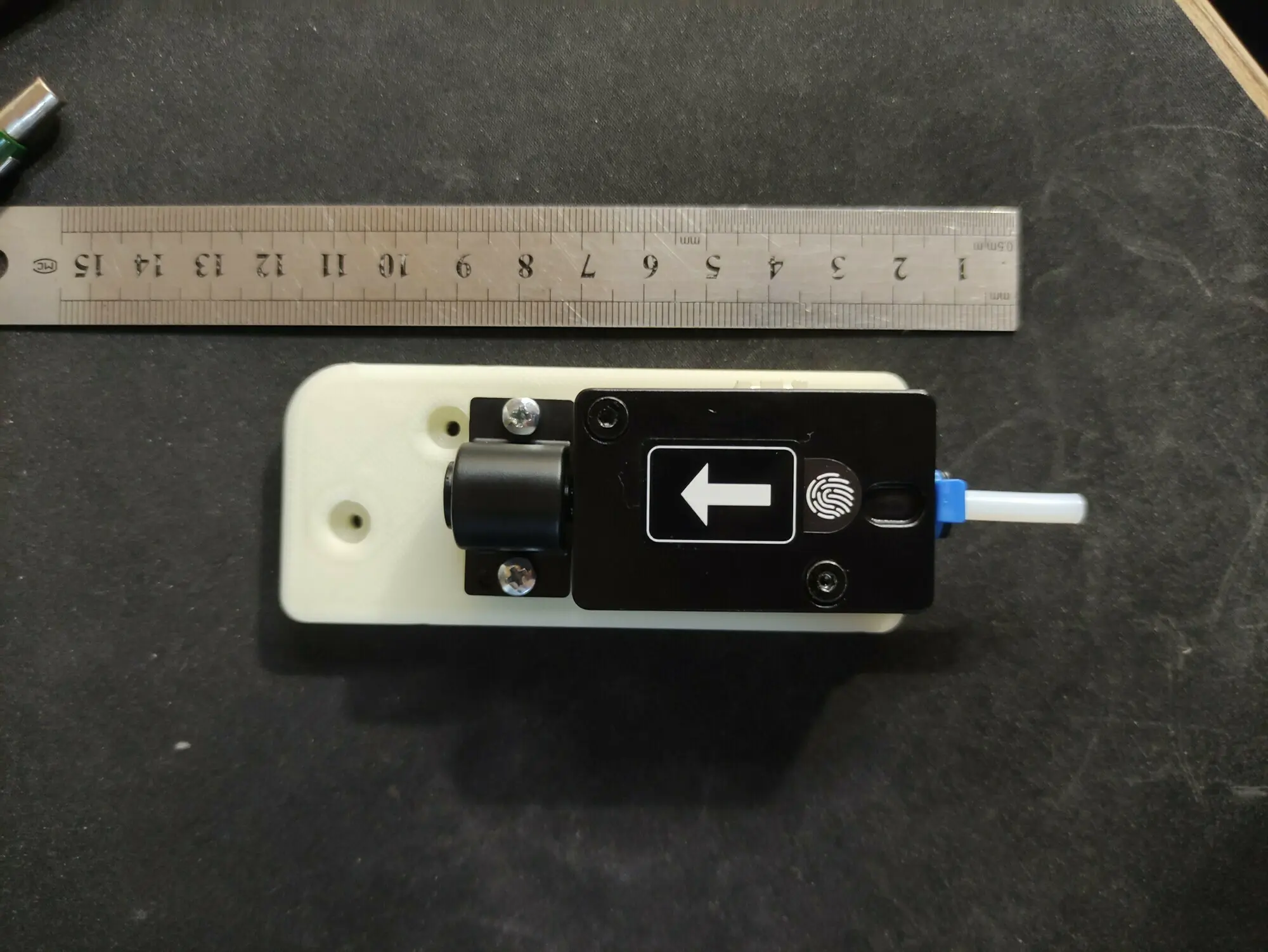

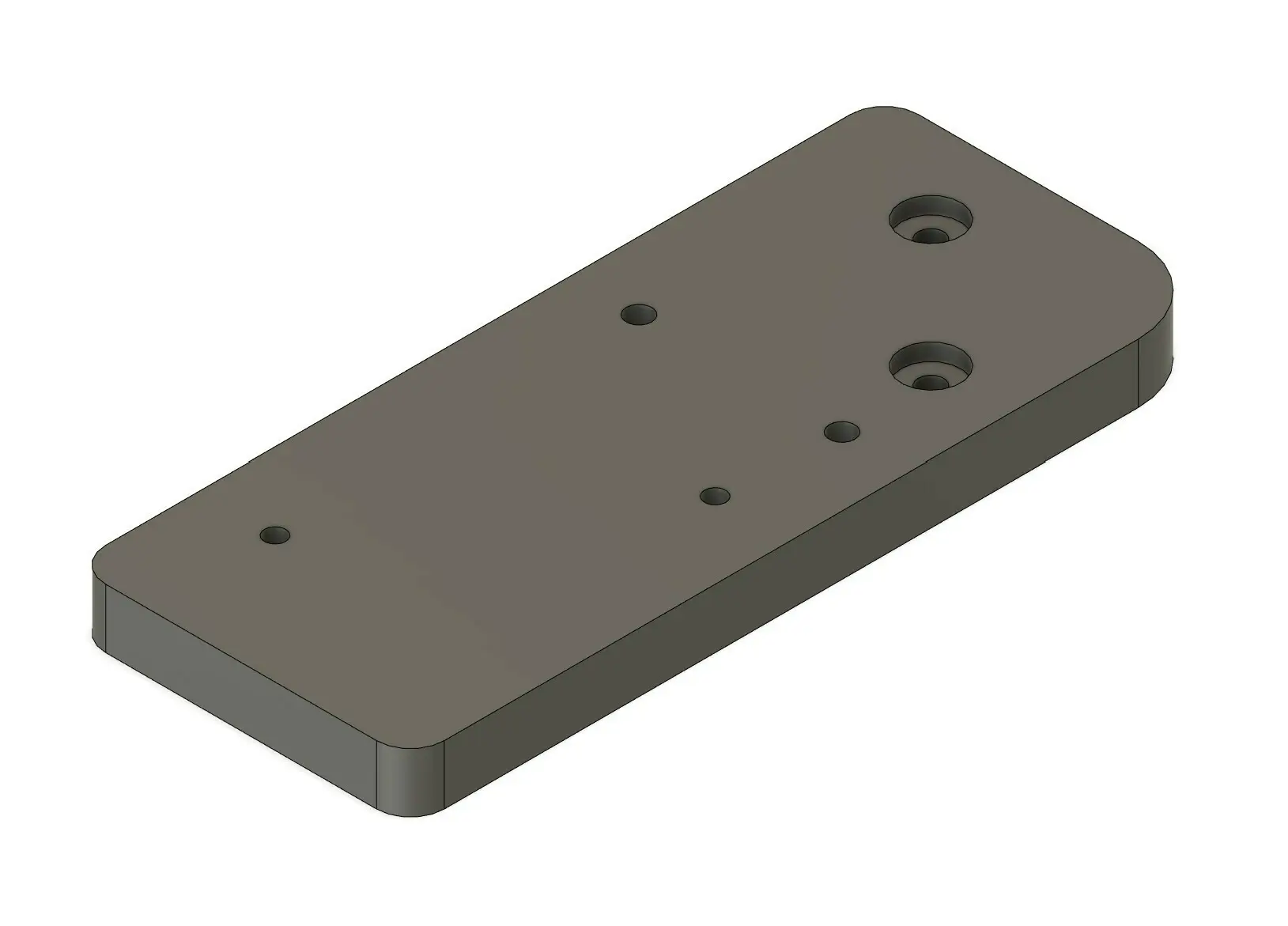

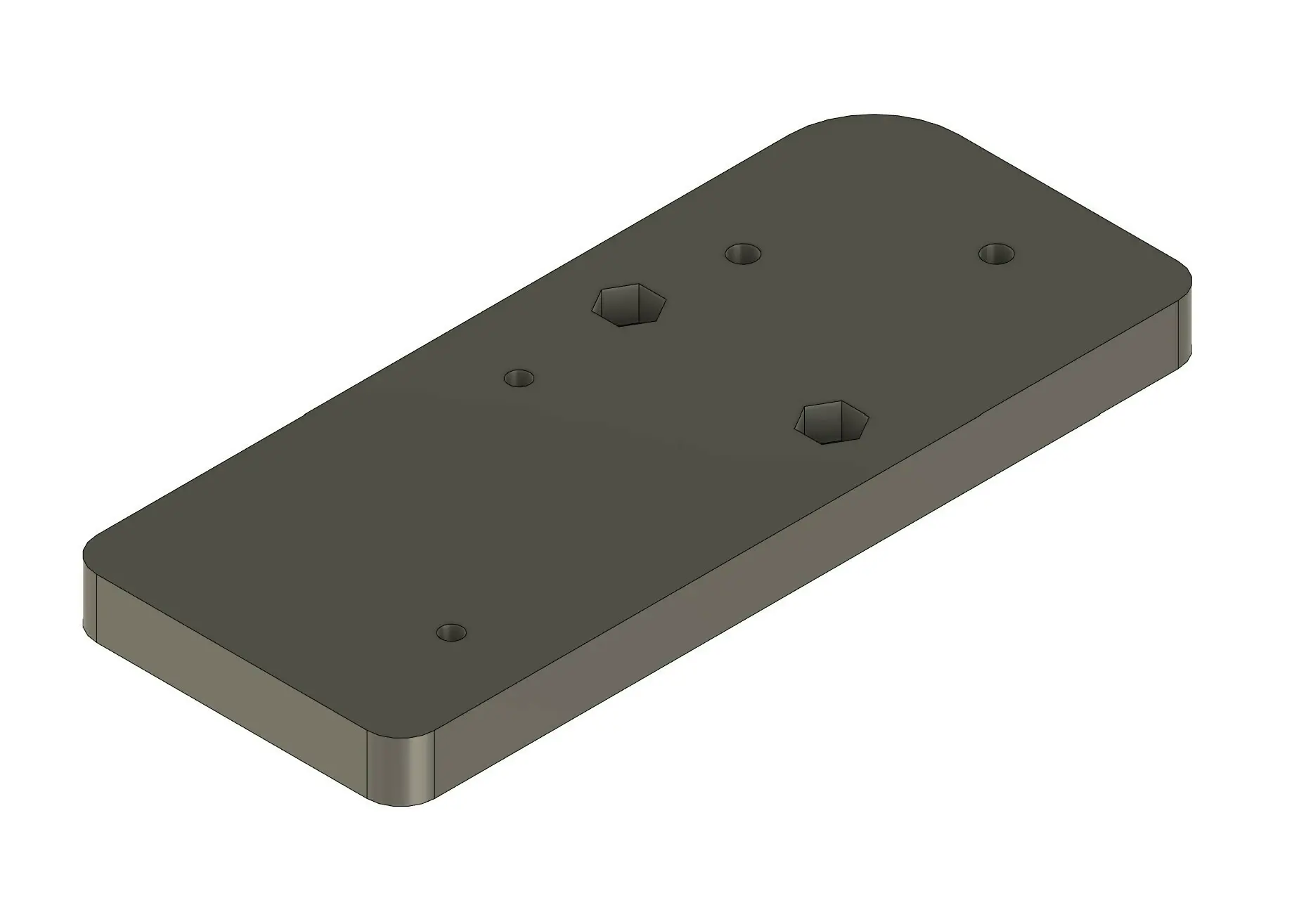

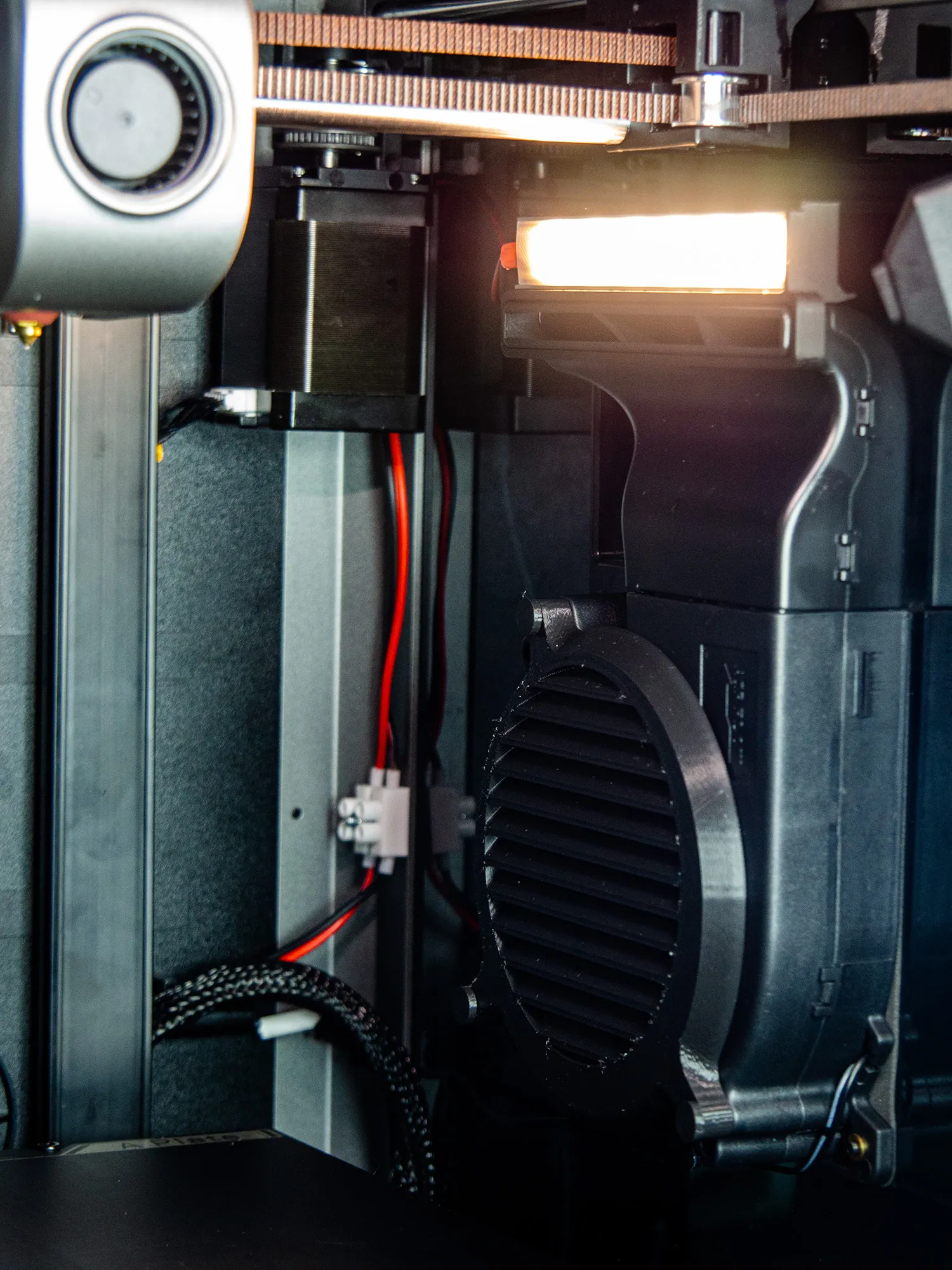

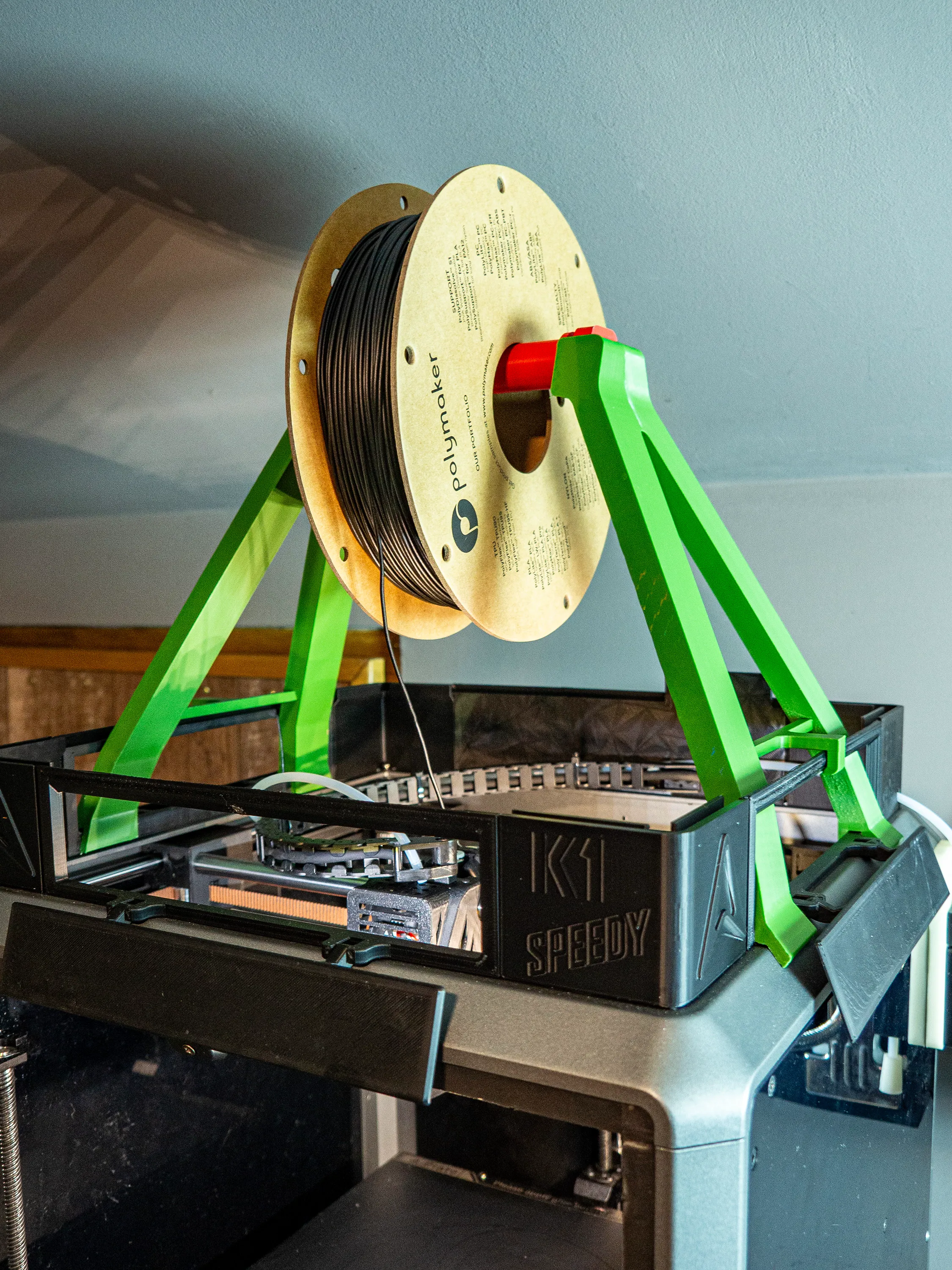

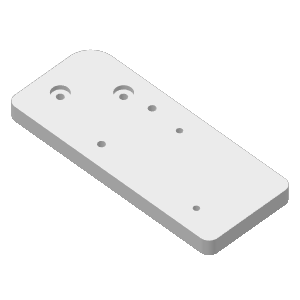

Creality K1, K1C runout sensor on right side

Category:

3D Printer Accessories

3D Printer Accessories

Print Settings (8)

Upload

0.2mm layer, 2 walls, 15% infill

K2

1 plates

19m 07s

12.79g

Ready to Print

Open with Creality Print

Download Print Settings

0.2mm layer, 2 walls, 15% infill

Creality Hi

1 plates

22m 13s

12.99g

Ready to Print

Open with Creality Print

Download Print Settings

See more

Package Download Files

Cloud Slice

Uploaded

14:52 09-20-2023

2.2K

43

Report

Standard License

This work is licensed under the Copyright License 4.0.

Standard License

3D Model files sold on Creality Cloud are available under a standard license, which has certain restrictions. In particular, these files cannot be used for any commercial use; it’s for personal use only. 3D model or any portion of the model in a digital or physical format may not be shared, transmitted, redistributed, remixed, duplicated, or sold.

Files (1)

Print Settings (8)

Upload

Makes

Add a Make

Comment

Picture